PLATING

RACKS

SUPPORT FRAMES

Line Type: Automatic Line

Used For: Electrolytic or Electroless Processes

Contact: Stainless Steel, or Copper, or No contact

Coating: Halar, or Polypropylene, or No coating

Our support frames can be built with or without metal contact points for the panel. They are most frequently used when coupled with our 'top loading clamps'.

Support frames act primarily to stabilize the panel while it is being electroplated.

With the use of vibration and other methods of agitation in plating tanks (to improve the solution flow inside the small vias), the bottom of the panel tends to sway a lot when held only at the top (using clamps). This swaying at the bottom can somewhat negate the desired effect of the agitation. In more extreme cases, if the agitation/vibration is too strong, panels run the risk of simply dropping out of place.

Our support frames fasten the panel in place at the bottom with the use of thumbscrews.This keeps the panel tightly in place, allowing the vibration/agitation to work fully on the piece being plated.

The support frame also acts as added security to ensure the panel can't fall out of place when vibration is present on the line.

If requested, we can also build contact points along the bottom of the support frame. Combined with the clamps making contact at the top of the panel, this combination gives superior results in terms of plating distribution.

Advantages:

- Provide Support to let vibration/Agitation work properly upon the panel

- Provide security against panels dropping due to high vibration

- Provide current to the bottom of the panel (when desired), for better plating distribution

- Necessary for plating flex /Rigid flex panels when using top clamps

T: 514-335-2436

F: 514-335-6008

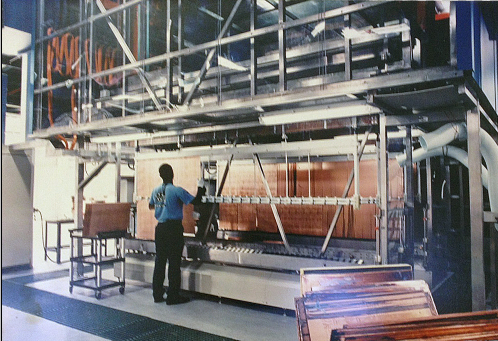

Support Frame with top clamps.

Image: Courtesy of Viasystems, Toronto